alvin l nunley

Site Supporter

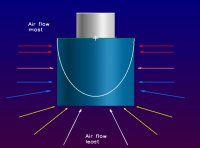

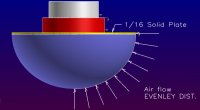

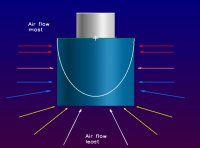

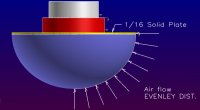

I have no way to prove this, but I believe this is how it works. I believe the white line represents the pressure differential boundary between the vacuum in the carburetor and the surrounding air pressure. The farther you get away from the carburetor, the lower the pressure differential difference.

Assuming I'm right, the more contaminated the filter becomes in the high flow area, adding resistance to flow, the farther the red lines would move from the carb opening. Moral; keep the filter clean!

Assuming I'm right, the more contaminated the filter becomes in the high flow area, adding resistance to flow, the farther the red lines would move from the carb opening. Moral; keep the filter clean!

Last edited: