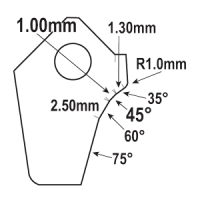

A while back I ended up with a head in a box of junk a customer brought me that was destroyed when the head broke off the exhaust valve. He said the head was "very expensive" and one of the best out there. He wanted me to try to figure what if anything was special about it. I cut the intake seat in half with a cutoff wheel to get it out of the head. Looking at the intake seat from the end of the cut in an optical comparator it looked like it was cut with a blade that is very close to, but not exactly like this blade I just happened to have laying around in the shop for some reason. The difference being that there was a radius where the 60 transitioned to the 75. It didn't look weird when looking at it from above when it was still in the head. If really didn't set of any red flags visually. The head did not come from anyone mentioned in this thread. That's all I got to add

Coming up with a tool that can measure the depth, width, and degree of a specific valve angle set in a cast head is not the easiest of tasks either -- nor is it to interpret its use in the tech barn to make a definitive call.

I've seen valve seats cut with a cutter similar to the one you've shown, and have also seen the "infinite radius" seat cutters.

There IS an advantage in flow and HP. I can't speak for the clone engines specifically because I simply don't work on enough of them to have a good data set.

Also, it's hard for me to believe that any builder is smoothing the inside radius enough that you can feel/see it in tech, yet it doesn't flow better. Good and bad port work aside. That inside radius is critical to air flow. That's the whole reason we have a "defined edge" rule!

As tech men (and most of us are engine builders as well,) we are put in yet another precarious position on this deal.

It's nothing new though -- we have had the problem of unenforceable rules (ie no tools or specific measurements to go by) for many years in this sport. Give us some measurements to go by, and we can both build and enforce them in tech. Without measurements

and tools, this is what is bound to happen.

With that said...a Big "thank you" to all who are willing to be tech men in our sport...and to Don, Tuttle, Lewis, and others who are working on this deal to make it better. The "easy" answer in all of our eyes, is not always so easy to implement, unfortunately.

-----

Thanks and God bless,

Brian Carlson

Carlson Racing Engines

Vector Cut

z

www.CarlsonMotorsports.com

Carlson Motorsports on

Facebook

33 years of service to the karting industry ~ 1Cor 9:24

Linden, IN

765-339-4407

bcarlson@CarlsonMotorsports.com