"So i got new bearing cassettes as my old ones were messed up and they dont fit right."

^^^^^^^^^^^^^^^^^^^^

>>>>Your new ones don't fit right either so there's NOTHING wrong with either your old or new cassettes, except for the old maybe being wor inside some from bearing movement while racing.<<<<

_________________________________________________

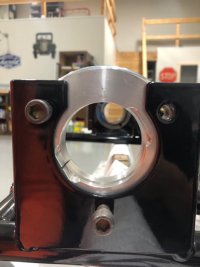

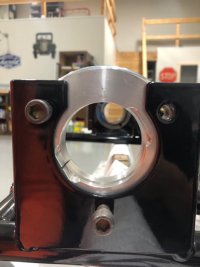

Looking at the picture in post #4 The bottom hole in the hanger looks ok along with the hole in the hanger on the top left of the picture.

Use the top left hole and the bottom hole in the hanger and it will also center the bearing per described in post #2.

Then your going to have to elongate the hanger hole on the top right per picture in post #4 to allow the top right bolt to be inserted without stressing anything.

The bad of it is it's also going to move the right side bearing forward shortening the chassis on the right side which is probably not what you want when done.

Because of that it looks like your whole chassis once upon a time took a big hit and was tweeked or was never manufactured correctly.

Once you have the right side bearing established and in place without having to force anything to install it you need to look to see how the axle aligns 90 degrees with your right side frame rail which will mount your engine. If your axle is at 90 degrees or square to your outside engine/frame rail, your ok.

But I suspect it will probably be more then 90 degrees because the chassis was hit and tweeked over all.

Lastly to get it in square your going to have to either elongate front and back the hanger holes on the left side hanger or get a cassette if they still make them so you can move the left end of your axle forward or back.

Over all the fix you need will shorten your chassis which is not bad and good if you race smaller ovals.

And elongating the holes on the left or getting a cassette which adjusts forward and back will allow you if you want to move the left end of the axle forward, as in so called late model rear steer.

When and if you move the axle on the left forward beyond square you may find it help you when you need to turn down mid corner off.

Either way it appears you've been riding a bent chassis which probably has been giving you fits 'loose in' because the back end has been bound up in general. You should pick up speed both entering the corner and off the corner with each being helped by having your chassis not in general all bound up and tight in the back. Or not because this is all just IMHO and ain't necessairly right anyway. ...

If it's a new chassis for you and you've never put it on the track then fix the bearing hanger holes by elongating on on your rear hanger and all three forward and back on the left. You never ever want to stress stuff to get thing to bolt together. Putting a chassis together is about hanging parts on easily and then adjusting via what ever is needed so you can hang parts easily in the right location on your chassis. If all your parts are neatly and easily in place and in the right location to have your chassis square, all that's in-between is just a piece of steel which can now flex per either it's design or degradation. Some flex to even too much flex is not necessairly a bad thing depending on track conditions and how much hp your using.

edit: all you have to do to fix it is to buy a rat tail file the diameter of your bolts and file the hanger holes forward or back as needed.

If you buy a good quality rat tail file with a little bit course teeth on it, elongating the holes by hand won't take very long.

You may want to scribe a level line forward and back below the holes, to follow when filing. Good luck and without being there were all just winging it with a fix.

BUTT the second picture for me tell it all, even though I'm clueless about it. ...