You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Circumference vs wheel width?

- Thread starter Nickp

- Start date

jaymancds

Member

Lot of variables at play here.Aproximately how much bigger is the Circumference if you were to mount the tire, measure, and then re-mount the same tire but on a 1/2" narrower wheel?

racing promotor

Moderator

You guess of an 1/8" to 1/4" is real close, more will be 1/4" than an 1/8"

I understand that. Just looking for an "approximate" value. I figured it wouldn't be much.Lot of variables at play here.

Thank you Sir. That's what I was looking for.Rough guess.....like mentioned lots of variables. I'd say 1/8"-1/4" (+/-) bigger in circumference......I know some that have 8.5 & 8.25 LR wheels to play with stagger without swelling or shrinking tires.

Again.....big pile of variables at play here.

racing promotor

Moderator

If your putting a value of 1 to 10 on a 1/4" more rear stagger when needed it would an 8 or more !!

CarlsonMotorsports

Site Supporter

Depends on tire brand as well.

Some mount up bigger than others on narrower wheels.

We've been mounting sets of Burris 33s and Hoosier D30As on 9 1/2" wide wheels (simply out of necessity - ie lack of 10" wheels) and they have been rolling out 34 1/4." After cutting and a little shrinking, they're right back at 34" where we want them.

-----

Thanks and God bless,

Thanks and God bless,

Brian Carlson

Carlson Racing Engines

Vector Cutz

www.CarlsonMotorsports.com

Carlson Motorsports on Facebook

32 years of service to the karting industry ~ 1Cor 9:24

Linden, IN

765-339-4407

bcarlson@CarlsonMotorsports.com

Some mount up bigger than others on narrower wheels.

We've been mounting sets of Burris 33s and Hoosier D30As on 9 1/2" wide wheels (simply out of necessity - ie lack of 10" wheels) and they have been rolling out 34 1/4." After cutting and a little shrinking, they're right back at 34" where we want them.

-----

Brian Carlson

Carlson Racing Engines

Vector Cutz

www.CarlsonMotorsports.com

Carlson Motorsports on Facebook

32 years of service to the karting industry ~ 1Cor 9:24

Linden, IN

765-339-4407

bcarlson@CarlsonMotorsports.com

Nick also remember if you start swapping wheel widths to keep an eye on your rear tread width measurement.

Very easy to try and gain stagger but not move the wheel to where you want it. Simple mistake trying to find a gain can send you in the wrong direction. Just a heads up.

We are a 2 man team so I try to eliminate all the things I could overlook while we wrenching.

Very easy to try and gain stagger but not move the wheel to where you want it. Simple mistake trying to find a gain can send you in the wrong direction. Just a heads up.

We are a 2 man team so I try to eliminate all the things I could overlook while we wrenching.

alvin l nunley

Site Supporter

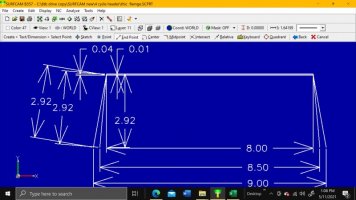

I made drawing in my CAD/CAM program.Thanks for all the help everybody!

8 inch tire on an 8 inch rim, sidewall straight up and down. 8 inch tire on a 8 1/2 rim, the sidewalls are at an angle. The difference in overall height is .011". That's the radius, the diameter would be twice that. If I mount that same tire on a 9 inch round, the height of the sidewall is now .050" less in height, versus straight up and down

Real world numbers might be different, but that's how it plays out in my CAD/CAM program.

alvin l nunley

Site Supporter

atwoodracing20

Dew Dawg

Brian does that change the spring rate of the tire much with a narrower wheel? Like mounting a tire on a 9 3/4 inch wheel instead of a 10 inch? White Vega tire.. thanksDepends on tire brand as well.

Some mount up bigger than others on narrower wheels.

We've been mounting sets of Burris 33s and Hoosier D30As on 9 1/2" wide wheels (simply out of necessity - ie lack of 10" wheels) and they have been rolling out 34 1/4." After cutting and a little shrinking, they're right back at 34" where we want them.

-----

Thanks and God bless,

Brian Carlson

Carlson Racing Engines

Vector Cutz

www.CarlsonMotorsports.com

Carlson Motorsports on Facebook

32 years of service to the karting industry ~ 1Cor 9:24

Linden, IN

765-339-4407

bcarlson@CarlsonMotorsports.com

SoCo Tire Treatments

Moderator

I know you asked Brian, but yes going to a narrower wheel changes the spring rate of the tire. Lowers the spring rate.Brian does that change the spring rate of the tire much with a narrower wheel? Like mounting a tire on a 9 3/4 inch wheel instead of a 10 inch? White Vega tire.. thanks

Brian i believe is only doing it out of necessity with 10" wheels so hard to get.

CarlsonMotorsports

Site Supporter

There are times when I prefer a narrower right side wheel - ie temporary track surfaces like fair racing, very sandy / porous surfaces like horse arenas, or on grass and ice. 99% of the time, you want 10" right sides.

If you need more side-bite, a narrower right side wheel will help.

Some of our new customers have no wheels and tires at all, and for what the price of used are going for, we outfitted them with 1/2" narrower right sides which will work just fine for their application (no bite track, etc.)

It definitely changes the spring rate as Earl explained. Some brands significantly more than others, depending on the sidewall construction.

Keep in mind, you can accommodate some of this with air pressure, but it's still a band-aid in my opinion.

If you need more side-bite, a narrower right side wheel will help.

Some of our new customers have no wheels and tires at all, and for what the price of used are going for, we outfitted them with 1/2" narrower right sides which will work just fine for their application (no bite track, etc.)

It definitely changes the spring rate as Earl explained. Some brands significantly more than others, depending on the sidewall construction.

Keep in mind, you can accommodate some of this with air pressure, but it's still a band-aid in my opinion.

paulkish

old fart

I know you asked Brian, but yes going to a narrower wheel changes the spring rate of the tire. Lowers the spring rate.

This is a question, not a statement.

Then it means when you lower the spring rate at a tire, the tire then needs less weight to compress.

The reason you need a lower spring rate in a tire, as my mentor "out east" explained to me during our first meeting around 15 years ago:

When track conditions warrant a lower spring rate it's because grip has gone away from the track.

And when track grip goes away the only thing that always happens is you will be going slower.

Because your going slower there are less on-track forces available to you to operate your chassis (the tires per this discussion).

Simply put lowering the spring rate makes it easier for your chassis to work as it did before track grip was reduced.

Then this offering brings up another question which is do you relate needed spring rate to your speed or track grip?

Another answer to my offering is because were talking about low hp karts with adjustable grip at the tire, when track grip goes away we may be able to compensate for it by changing tire grip and there will be no loss of speed. and ????????

But then again if you increase the tires ability to grip won't it still take more effort from going fast because to get the tire with more grip to work it will take more of your available hp or built up momentum. and lots of ?????????'s on that one. ...

Might it be more about how much effort it take to operate a tire changed spring rate then either speed or grip????????

dang you all cause me a lot of questions to thunk about ...

Last edited:

paulkish

old fart

Aproximately how much bigger is the Circumference if you were to mount the tire, measure, and then re-mount the same tire but on a 1/2" narrower wheel?

I think and hope you already got your question answered making my wonderings about the replies ok. and ???????

Did you?

SoCo Tire Treatments

Moderator

This is a question, not a statement.

Then it means when you lower the spring rate at a tire, the tire then needs less weight to compress.

The reason you need a lower spring rate in a tire, as my mentor "out east" explained to me during our first meeting around 15 years ago:

When track conditions warrant a lower spring rate it's because grip has gone away from the track.

And when track grip goes away the only thing that always happens is you will be going slower.

Because your going slower there are less on-track forces available to you to operate your chassis (the tires per this discussion).

Simply put lowering the spring rate makes it easier for your chassis to work as it did before track grip was reduced.

Then this offering brings up another question which is do you relate needed spring rate to your speed or track grip?

Another answer to my offering is because were talking about low hp karts with adjustable grip at the tire, when track grip goes away we may be able to compensate for it by changing tire grip and there will be no loss of speed. and ????????

But then again if you increase the tires ability to grip won't it still take more effort from going fast because to get the tire with more grip to work it will take more of your available hp or built up momentum. and lots of ?????????'s on that one. ...

Might it be more about how much effort it take to operate a tire changed spring rate then either speed or grip????????

dang you all cause me a lot of questions to thunk about ...

We been doing this all along, changing spring rate, just been doing it with internal treatments.This is a question, not a statement.

Then it means when you lower the spring rate at a tire, the tire then needs less weight to compress.

The reason you need a lower spring rate in a tire, as my mentor "out east" explained to me during our first meeting around 15 years ago:

When track conditions warrant a lower spring rate it's because grip has gone away from the track.

And when track grip goes away the only thing that always happens is you will be going slower.

Because your going slower there are less on-track forces available to you to operate your chassis (the tires per this discussion).

Simply put lowering the spring rate makes it easier for your chassis to work as it did before track grip was reduced.

Then this offering brings up another question which is do you relate needed spring rate to your speed or track grip?

Another answer to my offering is because were talking about low hp karts with adjustable grip at the tire, when track grip goes away we may be able to compensate for it by changing tire grip and there will be no loss of speed. and ????????

But then again if you increase the tires ability to grip won't it still take more effort from going fast because to get the tire with more grip to work it will take more of your available hp or built up momentum. and lots of ?????????'s on that one. ...

Might it be more about how much effort it take to operate a tire changed spring rate then either speed or grip????????

dang you all cause me a lot of questions to thunk about ...

As Brian pointed out, theres times where a narrower wheel would work, but 99.99% of those times a wider wheel, proper internal is the way to go. This is also the reason why theres a 10" wheel width rule. Have you ever seen how much faster a kart is with a 10.5" wheel on a good track, dont have to be a great track, its a difference

Right now wheels are very hard to come by, new ones arent available (mines been on order since beginning of January), but there are folks who have oddball sizing, the 9.5" and so on. At times you just got to make do with what you have, unfortunately.

Pete_Muller

Moderator

I can't speak AT ALL about dirt racing with any significant knowledge (I drove in one dirt race in my life... probably 25 years ago), but....

In sprint racing, I've always had the feeling that it wasn't simply the spring rate of the tire that changes, but also the "natural frequency" and spring rate of the axle/chassis/tire combination. As I'm sure many of you know, swapping the axle on a sprint chassis is method of tuning the handling, with axles often being classified as "hard", "medium" or "soft". Interestingly, this does not necessarily correlate to stiffest, less stiff, and least stiff. More often than not, the wall thicknesses can be the same. I believe these "labels" that have been applied have to do with how they "feel", (and technically, I believe it has something to do with what's called: "loss coefficient" -- roughly meaning "internal damping of the material"). Changing material type can make the axle be "livelier" or "deader" (for lack of better terms).

I have an interesting document on this subject, if anyone is interested.

(side note): Hub width is also a tuning method on a sprint kart, which I "suspect" ties into changing the stiffness and/or damping of a greater or lesser portion of the axle.

Do not mean to derail this thread about tire OD at all (I can start another topic if preferred), but since this moved from wheel widths / tire OD / to: spring rate, I thought I'd toss this in.

PM

In sprint racing, I've always had the feeling that it wasn't simply the spring rate of the tire that changes, but also the "natural frequency" and spring rate of the axle/chassis/tire combination. As I'm sure many of you know, swapping the axle on a sprint chassis is method of tuning the handling, with axles often being classified as "hard", "medium" or "soft". Interestingly, this does not necessarily correlate to stiffest, less stiff, and least stiff. More often than not, the wall thicknesses can be the same. I believe these "labels" that have been applied have to do with how they "feel", (and technically, I believe it has something to do with what's called: "loss coefficient" -- roughly meaning "internal damping of the material"). Changing material type can make the axle be "livelier" or "deader" (for lack of better terms).

I have an interesting document on this subject, if anyone is interested.

(side note): Hub width is also a tuning method on a sprint kart, which I "suspect" ties into changing the stiffness and/or damping of a greater or lesser portion of the axle.

Do not mean to derail this thread about tire OD at all (I can start another topic if preferred), but since this moved from wheel widths / tire OD / to: spring rate, I thought I'd toss this in.

PM

Freezeman

Site Supporter

Sign me up Pete, I am mainly a sprint racer and have been straightening all types of axles for over 10 years with a hydraulic jack jig.

I use a dial indicator to tell me how much movement I need to get a response which does corollate some with hardness of the axle I am working with yet it would also be interesting if my jig read pounds of pressure too.

I use a dial indicator to tell me how much movement I need to get a response which does corollate some with hardness of the axle I am working with yet it would also be interesting if my jig read pounds of pressure too.

Pete_Muller

Moderator

Yes: hardness changes the tensile and yield, but will not alter Youngs Modulus (the amount of flex for a given force within its yield limit).

Shoot me a private message with your email and I'll send you the document I mentioned.

Shoot me a private message with your email and I'll send you the document I mentioned.