Scarface5029

Member

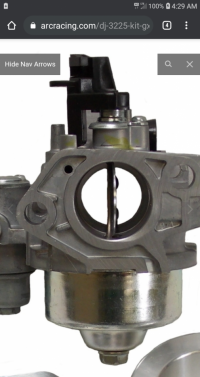

Hey guys I have a predator 212 with a dover holey Moses box stock carb with a 38 main I’m not sure of the e tube, a billet flywheel and rod, some head porting on exhaust and intake, 26lb white stripe valve springs, head shaved but not sure how much and a .09 head gasket and a big dog .930 header pipe, my question is what can I do or is it even possible to get my dyno cam cm cam to turn over 8,000 rpm and make good power without doing too much more work to the motor? Or should I get another cam? I’m currently turning it a little over 7,500 and running a small dirt track not sure the size but running 12/63 gearing. A new dover carb that is made for this type of setup is in the cards when I get the extra money. Thanks for any/all help.