You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dyno pump

- Thread starter jayo48

- Start date

Chris Cooper

Member

Notice any major changes in fluid temps ?

alvin l nunley

Site Supporter

The load cell in my dyno was very sensitive the ambient temperature. I would calibrate my load cell every time I ran the dyno.What are some signs of a pump going bad on a dyno? My engines are all of a sudden showing way low on power, 2 that I've fooled with, and 1 that I have touched. The one I havent touched is almost 1 hp off from just the 15th. Or I'm wondering if my load cell is going bad?

alvin l nunley

Site Supporter

flattop1

Dawg 89

From what i find you need data on the pump from day one and then compare that to current data .

Either flow or torque to turn it ,or output torque vs input torque .

Looks like all that might be more trouble then a new pump .

The only other thing would be an engine used just for testing and calibration purposes .

Either flow or torque to turn it ,or output torque vs input torque .

Looks like all that might be more trouble then a new pump .

The only other thing would be an engine used just for testing and calibration purposes .

alvin l nunley

Site Supporter

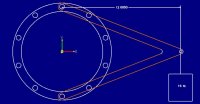

If you hang a 10 pound weight, as pictured, the strain gauge will put out an analog signal. My dyno hardware had a analog to digital converter. That digital number could be displayed on the computer. What ever that number was, I could tell the software that that number represented 10 foot-pounds of torque. I then removed the weight. During the run, As that number increased or decreased, the computer would display it as the curve, using that number as a baseline.The method al showed might be the answer to testing the load cell .

If you put10 lbs on the arm it should show 10 or real close .

Simple way to monitor it .

Because strain gauges are so sensitive to ambient temperatures, I believe dyno's need to be run in a controlled environment. Lacking that, constant monitoring of the ambient conditions is necessary.