You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine building question about tdc

- Thread starter paulkish

- Start date

Yes

Offset wrist pin in piston, or offset bore centerline to crank centerline.

Chevrolet did this in early sbc days to combat piston slap noise. Smokey Yunick turned the same pistons 180 in the bore to increase dwell at tdc.

Most tech is based on tdc, not necessarily at tdc only.

Ie, ignition timing. cam timing, etc.

Offset wrist pin in piston, or offset bore centerline to crank centerline.

Chevrolet did this in early sbc days to combat piston slap noise. Smokey Yunick turned the same pistons 180 in the bore to increase dwell at tdc.

Most tech is based on tdc, not necessarily at tdc only.

Ie, ignition timing. cam timing, etc.

Offset in rods can change TDC which effectively changes cam timing. But TDC is simply a matter of piston location. I am thinking you are asking about piston location relative to when the crank pin is centered in the bore? In tech that would be somewhat irrelevant as TDC is properly determined by piston location alone.

steve baker

Moderator

As chipg56 eluded to, in the tech they measure the highest position the piston reaches, so the crank pin location is irrelevant. So in other words TDC in tech is determined when piston is at the highest point above the block deck surface.Can a crank be ground in a way where before tdc the piston goes up higher then at actual tdc?

and is tech done at tdc only?

alvin l nunley

Site Supporter

Help me understand, you want to know if the piston can go higher once it's gone as high as it can go??Can a crank be ground in a way where before tdc the piston goes up higher then at actual tdc?

and is tech done at tdc only?

If you had a device that could measure to .000000", you would find that between .000" BTDC and .000" ATDC (as close as most instruments can measure to) there is a small amount of piston movement. That's what TDC (top dead center) stands for . The the position of the piston between those 2 numbers.

I'm sure you know, others may not, when the crankshaft is exactly mid--way between 90° positions, if the piston has a piston pin offset, it will not be at TDC.

You can Calculate that movement, but at 3 decimal places (most instruments) it's hard to see.

alvin l nunley

Site Supporter

For a real kick, offset wrist pin .050 to the side opposite rotation and look at piston dwell in degrees between .050 before and .050 after tdc vs straight up.

http://blog.wiseco.com/what-is-wrist-pin-offsetA little info from piston manufacturer.

http://blog.wiseco.com/what-is-wrist-pin-offsetA little info from piston manufacturer.

Last edited:

steve baker

Moderator

Good stuff, as piston location, dwell and piston velocity changes the torque and camshaft design design changes. Back in my Chevy SB race engine building days ( late 70's ) we studied the stroke vs rod length ratio and how this affected the piston velocity and crank angle when max velocity occurred.For a real kick, offset wrist pin .050 to the side opposite rotation and look at piston dwell in degrees between .050 before and .050 after tdc vs straight up.

http://blog.wiseco.com/what-is-wrist-pin-offsetA little info from piston manufacturer.

Steve

paulkish

old fart

was offset something a sign of when box stocks rattled when at idle on the grid?

was told often the ones that rattled were the good ones

edit: But we ran a house motor which didn't rattle.

I figure house motors were those far and few inbetween motors when done and put on the dyno just happened to give special high hp numbers.

They were then kept and the customer got something else which was good but not special.

was told often the ones that rattled were the good ones

edit: But we ran a house motor which didn't rattle.

I figure house motors were those far and few inbetween motors when done and put on the dyno just happened to give special high hp numbers.

They were then kept and the customer got something else which was good but not special.

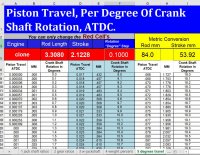

A study

Amazing how a simple change can throw all else out the window.

Every advance offers multiple opportunities for different camshafts.

The flathead is a great example of possible combinations.

Couple guys on here believe clone cam design has progressed to the ultimate already.Good stuff, as piston location, dwell and piston velocity changes the torque and camshaft design design changes. Back in my Chevy SB race engine building days ( late 70's ) we studied the stroke vs rod length ratio and how this affected the piston velocity and crank angle when max velocity occurred.

Steve

Amazing how a simple change can throw all else out the window.

Every advance offers multiple opportunities for different camshafts.

The flathead is a great example of possible combinations.