Skidude

Member

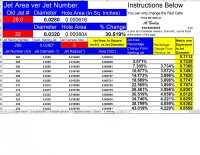

What size is the factory low speed jet and what size do most folks run for a purple plate engine? I’m running a factory low speed jet and a .038 main jet.

What type adjustment is the mixture screw? Is it a fuel adjustment or an air bleed? As you can tell, I’ve not yet taken the time to tear into one and see for myself.

What type adjustment is the mixture screw? Is it a fuel adjustment or an air bleed? As you can tell, I’ve not yet taken the time to tear into one and see for myself.