You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Predator flow numbers

- Thread starter Westy

- Start date

sneaks12303

Member

The Hemi will flow 85-90 @ .350" lift with a 32mm intake .

Depending how good the shop vac is you might need 2...

My flow bench kit claims 145 cfm @ 28"H20 from a single Sears detachable blower shop vacuum.

210 cfm @ 10".

http://www.flowperformance.com/blower_unit.html

That might do it for most 212 Predator parts, no?

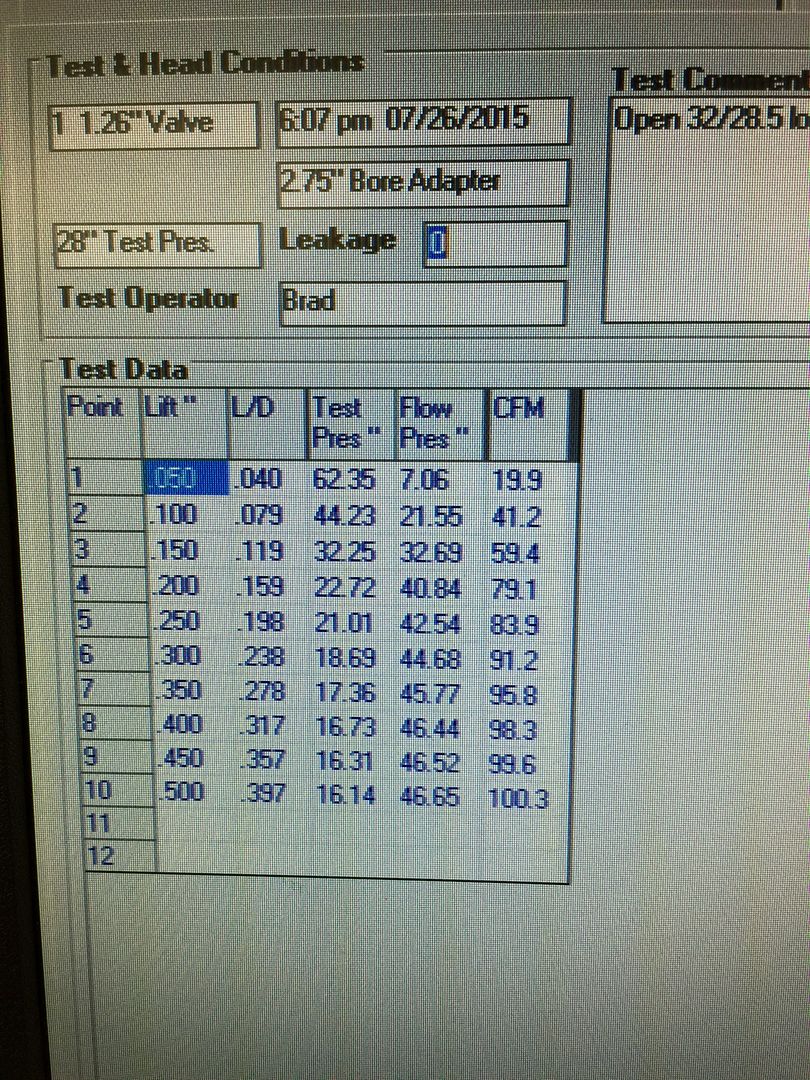

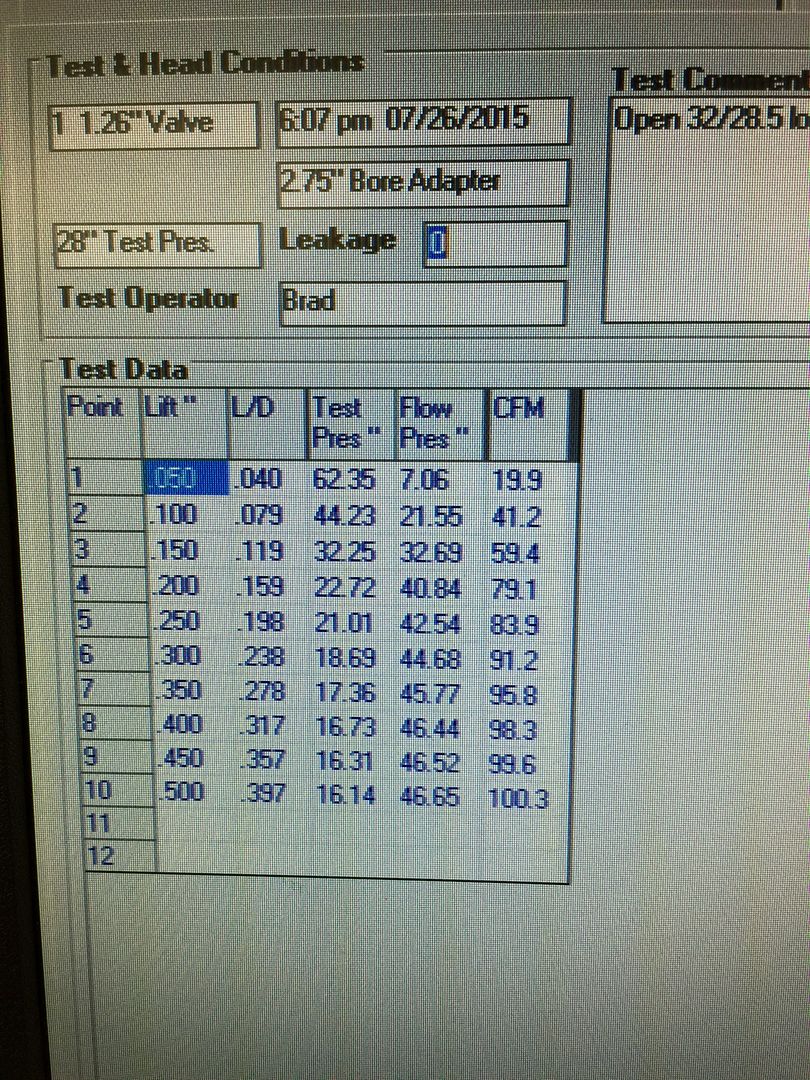

I just got the Performance Trends EZ Flow bench and I'm using a Fein Turbo vac. The Fein vac is pretty much a very high quality Shop Vac. I would think they will perform relatively the same. At 100 cfm actual test pressure is 16", which gets corrected in the software to whatever test pressure you choose. I sort of doubt one shop vac will flow anywhere close to 145 cfm @ 28". Like mentioned above you'll most likely need at least 2 to get that kind of flow. I could be wrong, but flow is flow no matter what bench you have.

youngengines

Member

I finally flowed a stock hemi that got 50 cfm.. the others have all been in the 48cfm range here.

standup guy

New member

BradH -That's a very nice looking welded up chamber, do you know what the combustion chamber volume is in cc? How small a chamber have you been able to achieve?

Jamie Webb

New member

Young, at what test pressure/depression are you using?

I use a single motor for mine. I'll have to look but pretty sure mine will get up to 145 at 28". I bought the motor/fan separate from an online vac parts/repair shop. It was about $100 just for the blower/vac motor.

I use a single motor for mine. I'll have to look but pretty sure mine will get up to 145 at 28". I bought the motor/fan separate from an online vac parts/repair shop. It was about $100 just for the blower/vac motor.

youngengines

Member

I use a large shop vac.. I would have to look and see what its actually pulling at max flow... I do know I used a smaller vacuum that wouldn't pull as much.. but the meter showed the same flow numbers..

Got my flow bench kit yesterday. Here are some numbers from a stock non-hemi 212 head intake port.

FP1 v4.9.6490 (C)2014

Flow Performance LLC

PS1=40 PS2=40

Pitot Mode

DAD 0.0747

.039 .022 0.0

z

;Edit

Predator 212cc non-hemi cylinder head

Stock head, valves.

Cylinder bore adapter 2.755 ID x 2.2" length

Clay radius on inlet port ~1/2" radius

;

Mode 1

New value: 2

z

28.0 19.4 19.3

28.0 19.4 19.4 < Mark 0.05

28.0 36.1 36.0

28.0 36.1 36.1

28.0 36.2 36.1 < Mark 0.10

28.0 48.9 48.8

28.0 48.6 48.5 < Mark 0.15

28.0 51.9 51.8

28.0 51.9 51.8 < Mark 0.20

z

28.0 53.2 53.1

28.0 53.0 53.0 < Mark 0.25

28.0 54.0 53.9

28.0 54.1 54.0

28.0 54.0 53.9 < Mark 0.30

Looking forward to seeing how much I can improve those with a dremel.

FP1 v4.9.6490 (C)2014

Flow Performance LLC

PS1=40 PS2=40

Pitot Mode

DAD 0.0747

.039 .022 0.0

z

;Edit

Predator 212cc non-hemi cylinder head

Stock head, valves.

Cylinder bore adapter 2.755 ID x 2.2" length

Clay radius on inlet port ~1/2" radius

;

Mode 1

New value: 2

z

28.0 19.4 19.3

28.0 19.4 19.4 < Mark 0.05

28.0 36.1 36.0

28.0 36.1 36.1

28.0 36.2 36.1 < Mark 0.10

28.0 48.9 48.8

28.0 48.6 48.5 < Mark 0.15

28.0 51.9 51.8

28.0 51.9 51.8 < Mark 0.20

z

28.0 53.2 53.1

28.0 53.0 53.0 < Mark 0.25

28.0 54.0 53.9

28.0 54.1 54.0

28.0 54.0 53.9 < Mark 0.30

Looking forward to seeing how much I can improve those with a dremel.

After a little work with a Dremel tool I was able to get 66 CFM, up from a stock 54 CFM at .3" lift., 28"H20. About a 22% increase.

I was hoping to get 70 CFM. I just worked the short side radius and the bowl area without touching the actual port walls.

This was a stock non-hemi 212 head intake port and valve.

I was hoping to get 70 CFM. I just worked the short side radius and the bowl area without touching the actual port walls.

This was a stock non-hemi 212 head intake port and valve.

sneaks12303

Member

Yep , Rounding That "short side radius" is worth a lot . Now is that a 27mm or 25mm intake valve ? The non hemi Preds come both ways ..

Yep , Rounding That "short side radius" is worth a lot . Now is that a 27mm or 25mm intake valve ? The non hemi Preds come both ways ..

The valve is 27mm. I did some more work on the short side radius and lost about 3 cfm. I had lowered the port floor as it approaches the radius.

When you remove material from the floor as it approaches the seat it needs to be minimal. The problem with the predator and clone head is that the air cannot be turned toward the valve. You can often pick up flow and lose power by doing this This is why the animal makes allot more power. Some will argue this but its just the way it is. Flowing air on the to the valve at an angle is a hp killer. A good animal motor will pull 9500 easily.

Joe Kraemer

New member

The valve is 27mm. I did some more work on the short side radius and lost about 3 cfm. I had lowered the port floor as it approaches the radius.

One thing you don't want to do is lower the floor. By lowering the floor you take some of the short side radius away and the air has no chance of making the turn then. On the next head I do I'm going to raise the roof as much as I can and fill the floor to give it a straighter shot at the back of the valve.