flattop1

Dawg 89

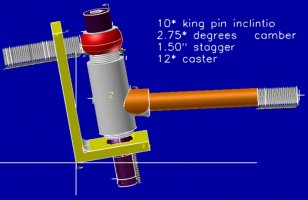

Interesting observation . Any camber adjustment will change king pin angle .I’m not saying you have to change spindles. I must be extremely bad explain things.

Example; let’s say you have a 2.75° spindle. You want 3.0° camber. All you have to do is make a .25° adjustment. I would think that would be a lot easier than making a 3.0° adjustment? Has karts are built today, that means you’re also putting another 3° into the kingpin inclination. This means you’re actually changing 2 things.

A 2* swing in camber on the right is pretty big . Factory teams may get some special spindels you never know .

As stated mass production makes comprimises for many reasons .

Additional- PRC did use a different L block when you went too the asphalt spindle on the left . Going from a 7.5 too a 5* . King pin inclination .

At that time there must have been a reason .

Last edited: