spincycle

Member

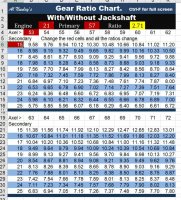

trying to find out if there is a formula/mathematics 2cycle racers use to help them figure out what rpm engagement to set up the clutch on the secondary side on a jackshaft...using 57/21 pulleys on the primary side, disc clutch and 35 chain/gears on the secondary side, looking to run engine at 14000 - 14500 max rpms...thx!