Interesting results.

I thought I'd add some info for the plate engine racers out there.

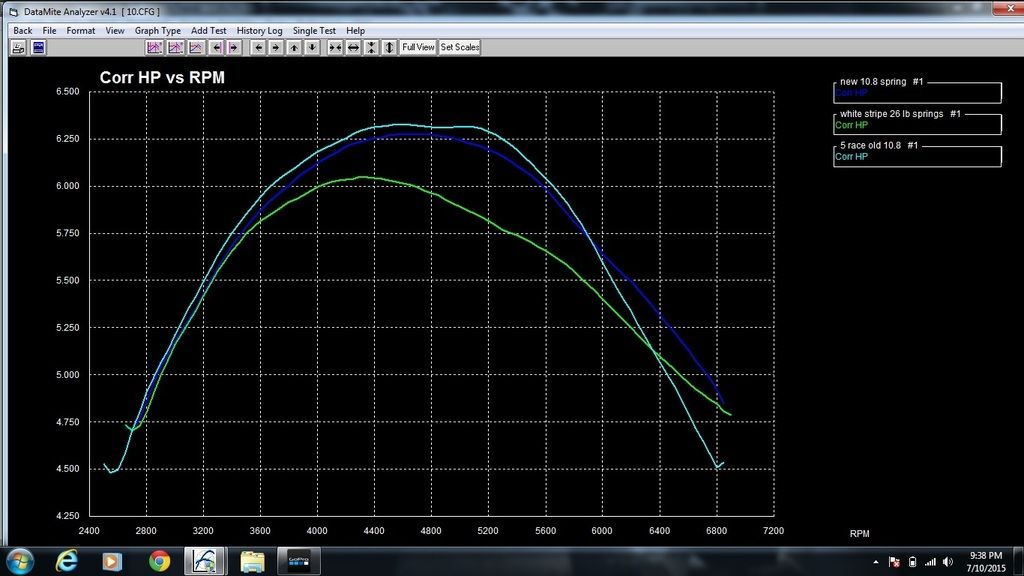

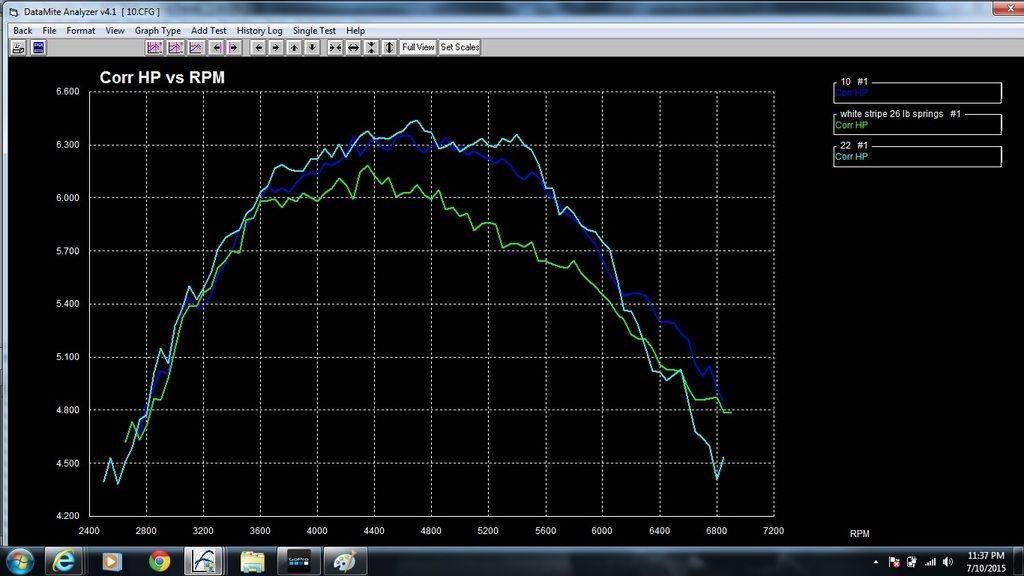

I thought I'd try to repeat what you tested with what I have on hand which was only new and used 10.8 lbs springs and some white stripe 26 lb spring.

Test criteria:

Go-Power water brake dyno, s beam load cell, Perf Trends Pro, pulls from high load to low load

purple plate clone

Engine allowed to cool between runs

gasoline

BSP3 cam

spring installed height is at .815"

ARC 6619 flywheel

ARC filter adapter

ARC blueprinted carb, rejetted for local conditions

JC3 big pipe w RLV silencer

BSP air filter

Notes:

Obviously the white stripes springs limited power in this engine. My guess is by excessive parasitic drag.

As expected, we see then that the newer 10.8lb springs performed better past the 6000 rpm mark when compared to the ones with 5 races on them. However, we also see some improvement with the 5 race old springs up to about 5800rpm. This is most apparent at 5200rpm.

So this goes back to controlling the lifter on the cam, perhaps the older springs allow the cam to throw the lifter off the lobe some extending the period of max lift or allowing the valve to open more than the cam lobe at rpm due to the valve train inertia overcoming the spring force. I.e. the lifter loses contact with the nose and backside of the cam lobe. Or perhaps the newer springs add just that much extra drag to be noticeable.

The profile of the HP curve with the older springs makes me think it's more than just drag, maybe some harmonic in the spring sets up.

All this seems to indicate that perhaps very frequent spring changes in the plate engines may not be that beneficial. Or perhaps, the stock weak springs may provide some benefit to a plate engine. More testing on my part is needed here.

Thoughts and opinions?