I read in another post about bracing. I didn't want to hi-jack that post so I'll ask here. Where are you guys bracing the blocks in modified builds? Lifter area? I'm in the process of gathering enough parts to build one and would like to make it as bullet proof as I can. Thanks' in advance for replies.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bracing the block??

- Thread starter W Lindsey

- Start date

Billet side over the way to go.

It makes the most sense!

WinstonSmith

New member

I picked up a lot of good ideas from Sneaks and shamelessly copy him...

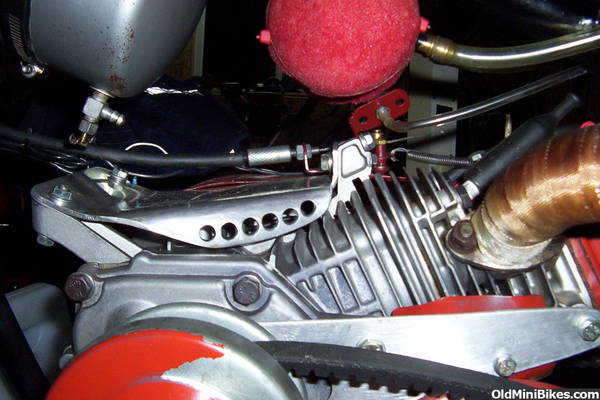

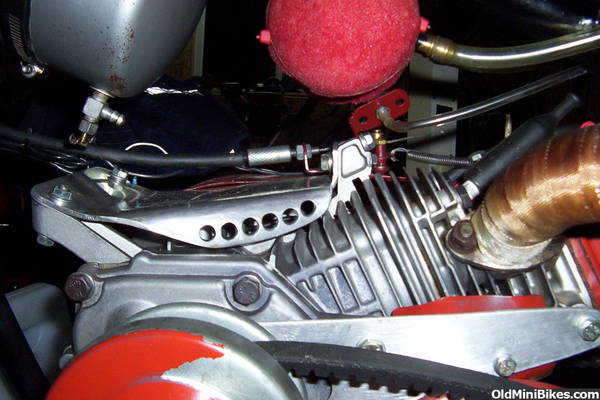

This one is a little hard to see but it connects the case PTO flange to the head.

I found this reduced some of the stresses that loosened up my case cover.

This engine ran 2 seasons without issues once the bracing was added.

Before that I had to watch those bolts close.

This one is a little hard to see but it connects the case PTO flange to the head.

I found this reduced some of the stresses that loosened up my case cover.

This engine ran 2 seasons without issues once the bracing was added.

Before that I had to watch those bolts close.

Personally....I believe 'sheet mat'l' support too be prone too harmonic vibration that could make things worse, instead of better. Not trying too denounce anybodies efforts, but time and testing will tell. Expensive as they are, the billet side-cover is the best approach on the PTO side. On the opposite/flywheel side, a 'plate' is needed (i've started on one) too 'joint' together the 4-holes around the crankshaft, housing a third bearing (as sneaks has done) in addition too picking up the (2) coil mounting bosses via re-configuring them and mounting the coil too the 'plate'. In my own mind, I am trying too justify the need/effort towards the stiffener support plate(s) on the front an top of the motor. I could be wrong....who knows.

Also what is that inside a windage tray?

I find that interesting as well! I have made serveral of plates/baffels such as that and they are intended too act as 'anti-sloush' plates to minimize 'oil sloush' in the crankcase, primarily on 'oneway' oval tracks. I can't say they really 'work' and i've given several units out for people to try, while No body has said they Didn't work.

sneaks12303

Member

Heres some idea's

sneaks12303

Member

Carb bracing . U can B creative here...

sneaks12303

Member

Head to block and the chain guard is an excellent brace . Try to catch the 3rd hole in the side cover . Many don't..

sneaks12303

Member

The top plate and the steel throttle bracket are also incorporated into the block bracing

sneaks12303

Member

Behind the flywheel

sneaks12303

Member

If your SA has 20+ hp U may want to consider a 3rd bearing ...

sneaks12303

Member

BTW - The WinstonSmith design is awesome .

sneaks12303

Member

I picked up a lot of good ideas from Sneaks and shamelessly copy him...

This one is a little hard to see but it connects the case PTO flange to the head.

I found this reduced some of the stresses that loosened up my case cover.

This engine ran 2 seasons without issues once the bracing was added.

Before that I had to watch those bolts close.

I luv it when U guys take my homemade Poboy stuff and turn it into "Design Art"...That is great

BTW - The WinstonSmith design is awesome .

I agree there!!!!

Did either of you WinstonSmith or Sneaks make a template or drawings for your braces? I would love to get a copy of them if you did.