older n dirt

Member

So will 55s not work&why

Good question, I'de like to know too.

So will 55s not work&why

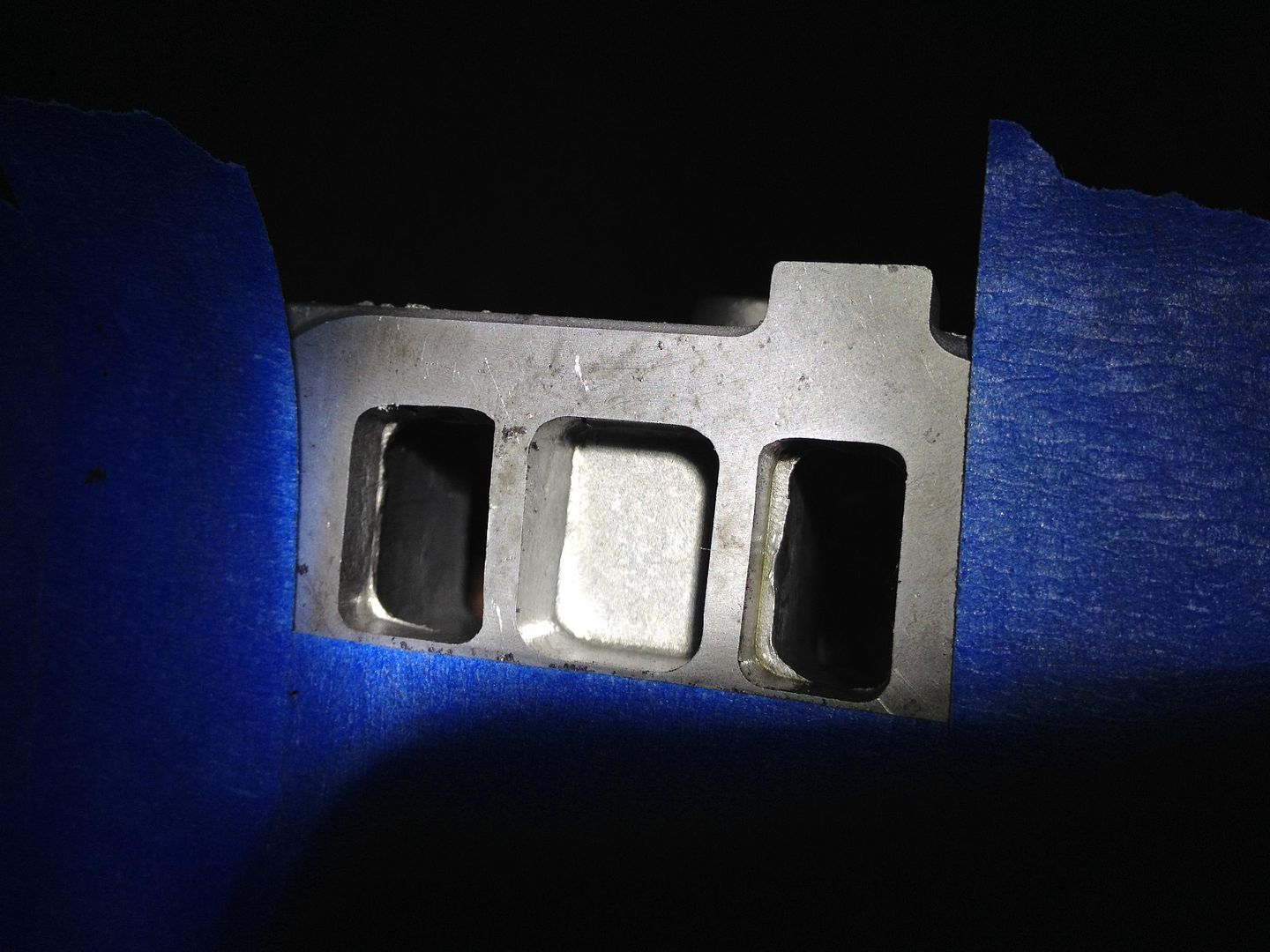

I agree . I was worried about the thin base after cutting spring pockets for duels so I used longer valve stems and cut my own keeper groove. This eliminated the need to go deep, Just a bit wider..I wasn't trying to be mean, I hope it didn't sound that way. The problem I see, is the way I port (raise the intake port), it get's real thin at the spring pocket (the angle of the valve makes it that way).

If it works for you do it. I won't say you are wrong. I'm just saying what I have found out through many years of testing by the major cam companys. Lighter weight makes a big difference on the valve side of the rocker but very little on the pushrod side. Also larger pounds of spring and rates make the longer pushrods flex more.

What size push rods will I need with hemi head cut 80,ss valves,55#springs,307nr cam?

on one of my hemi motors, with an NR Racing race head (milled .080)

One of the first steps to a quality build is to remove casting flash and deburr.