Jon Brogden

Member

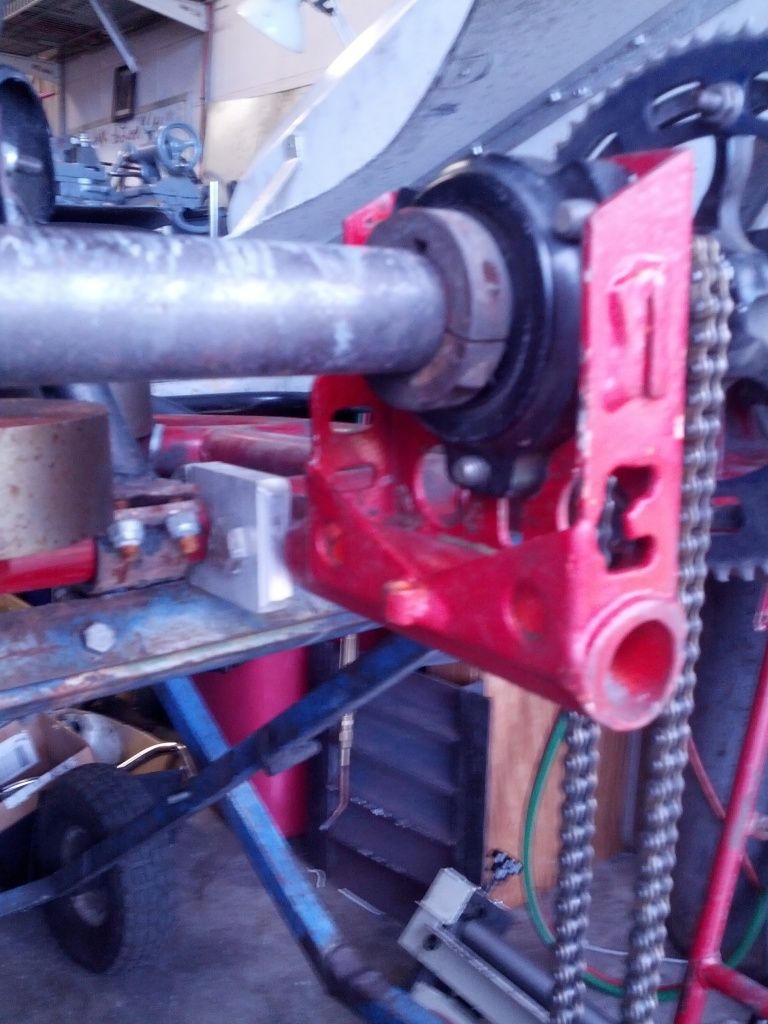

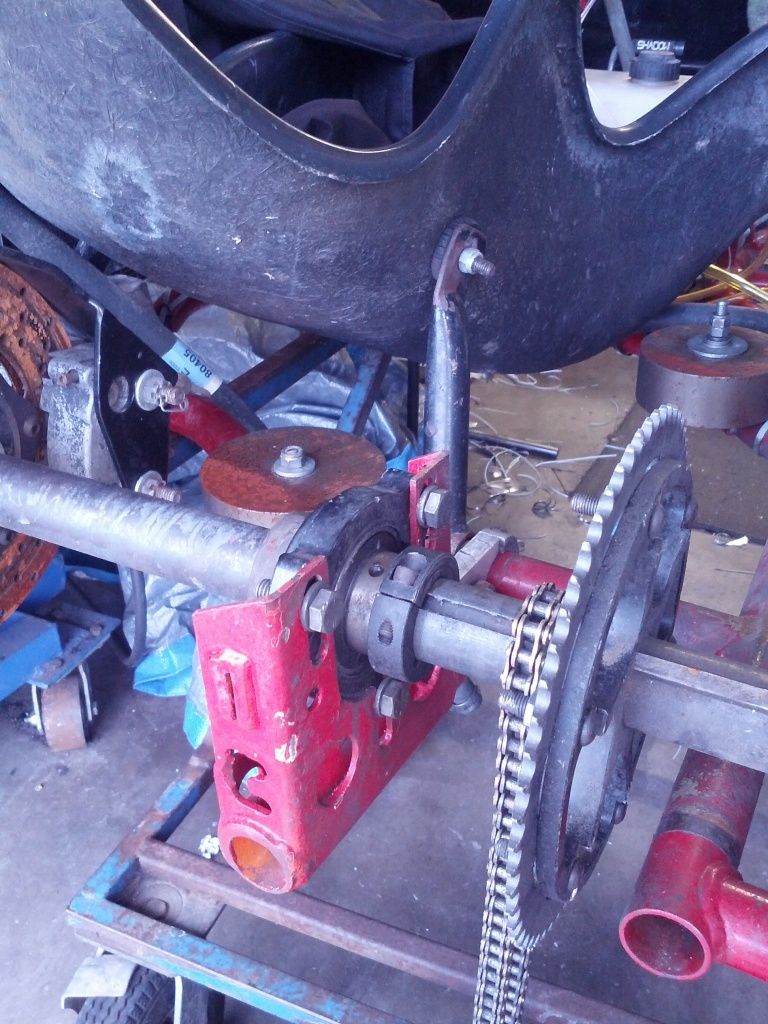

Ya, definitely will mock it up and make lower plate with some adjustment right and left to dial in left side percentage, It may need to go as far to the left as I can muster, won't know for sure until I can get it on some scales. How thick do you think that plate needs to be to be rigid enough?